Webasto

Introduction to all models

Charge cyclers for automobiles

Power processing & DC componenet test system

Webasto Power Processing systems products. Which used for battery performance by vehicle manufacturers, certifying agencies, battery AC/DC manufacturers. The instruments application includes

- Battery Cycle Testing – charge/discharge

- Hardware loop in testing – Power requirement of each components

- Drive cycle testing- USABC , federal motor vehicle test & European standrards (Indian will also be included)

General advantages

Units are smaller, produce less noise, supplied with wheels one person can push it to the place where required. Tested for 10days continuous usages. It is also supplied as single unit not as stacks. Known for reproducible results. Instrument is connected to computer via serial port and optional Individual cell monitoring. System also contains isolation transformer.

Loop in test

Our power processing products are capable of a wide variety of testing and development applications with the flexibility to implement virtually any drive cycle for the electric, hybrid electric and fuelcell vehicle. In recent years with electronics and vehicle systems becoming more complex our equipment is typically being used for hardware in loop testing for vehicle development. High voltage and high current system meets any type of vehicle requirements.

Battery Pack Cycle testing

Instrument has bi-directional flow facility means while discharging AV systems takes power from your system and the same power is given back to your battery. The heat generated during power lose due to charge/discharge is dissipated by internal water circulation. No air means less noise. Internal water circulation means no need for water taps. Response time is very fast with 10ms.

Drive cycle testing

One can perform any standard drive cycle test. Instrument is supplied with programs to

simulate USABC and Federal Motor Vehicle test standards. To modify any changes scripting

programs are provided. One can easily add or modify.

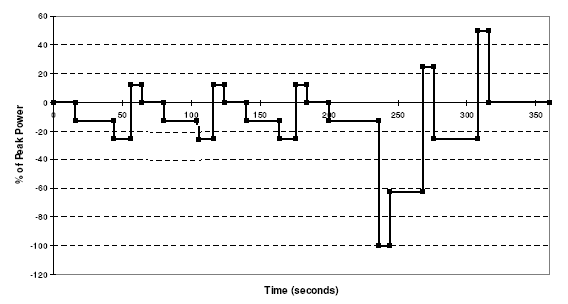

Drive Cycle Testing

Plot of Cycle File

LabView or other software that can control the ABC units. GE worldwide currently using many of our systems, GE India (Bangalore) has several ABC-150’s and MT-30’s, while GE USA (New York) has several ABC-150’s.

Instrument Block Diagram

American automotive companies are using AeroVironment’s equipment as a battery simulator in hardware-in-loop testing. Diagram attached. Also attached the drive cycle testing. One can also use a software simulation programs (i.e. MATLAB), to model the energy storage device characteristics (battery, fuelcell or ultra cap). These programs are then transmitted thru a CAN bus to control AV’s equipment to perform as the energy source in the loop.

MT-30

MT -30

Dual Channel Charge Cycler

5 to 120V

Independent 330A/ Parallel 500A

Power 30kW

Discharge 99% efficiency

Power dissipated to grid

Pack tester- Two-wheeler

ABC-150

Two Channels Charge Cycler

+8-420V

264A Independent /530A parallel

125kW

Discharge995 effectively

Pack Tester Cars/SUV

900

AV900

Two Channels Charge Cycler

+ 8 -900V

500A Independent/1000A Parallel

250kW

415V/50Hz

Pack tester for trucks/buses

Discharge Efficiency– 99%

Regenerative ( back to grid)

900EX

AV900EX

Two Channels Charge Cycler

+ 8 -900V

500A Independent/1000A Parallel

250kW (extendable to 1MW)

415V/50Hz

Pack tester of trucks

Discharge Efficiency– 93%

Regenerative ( back to grid)